Common automatic buckle machine category features

Common automatic buckle machine is widely used in food, medicine, hardware, chemical, clothing, postal and other industries, suitable for carton packaging, paper packaging, parcel letter packaging, medicine box packaging, light industry packaging, hardware tool packaging, ceramic packaging , auto parts packaging, daily chemical packaging, stylistic supplies packaging, equipment packaging and other automatic packaging and packaging of various sizes.

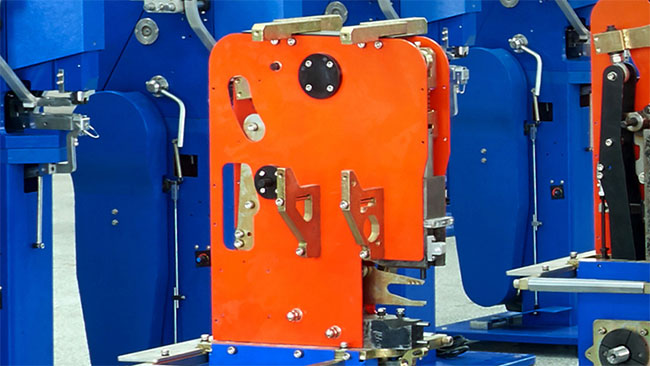

Features: Modular aluminum alloy bow frame design, easy to assemble and disassemble; fully automatic design, easy to operate and use; the maximum size of the bale is determined by the bow frame, the bow frame can be customized according to the needs of users; motor, reducer, cam The operation of the tightening arm is excellent; the packing tightening force is excellent, the fault is less, the maintenance is convenient; the packing action is soft, the durability is excellent, the packing function is perfect; the motor stops immediately after the packaging is finished, and the power saving is practical.

The automatic buckle machine (high-standard standard type) can realize automatic packaging, but the table top has no power and needs to be manually pushed, and the packaged items can pass the baler. The principle of the baler is to use a strap to wrap the product or package and then tighten and fuse the ends by heat effects or using a material such as a buckle. The function of the strapping machine is to enable the plastic strap to be closely attached to the surface of the bundled package, so as to ensure that the package is not scattered during transportation and storage, and should be bundled neatly and beautifully. Strapping machine price: The price of automatic strapping machine or automatic strapping machine is more than twice that of semi-automatic equipment.

The standard automatic baler series products are continuous and reliable, the plastic belt is close to the surface of the package, the joint is firm, the machine is safe, and the working noise and smoke do not affect the health of the operator. If you are interested in us, please contact us: miller@fmbutton.com

Popular information

The origin of the plastic snap button and the funAug 27, 2019

The origin of the plastic snap button and the funAug 27, 2019 Automatic button machine: button inspection methoAug 27, 2019

Automatic button machine: button inspection methoAug 27, 2019 Points to be aware of when using a fully automatiAug 27, 2019

Points to be aware of when using a fully automatiAug 27, 2019 Fuming button, ingenuity, never stopAug 27, 2019

Fuming button, ingenuity, never stopAug 27, 2019 Plastic snap button accessories highlight the styAug 27, 2019

Plastic snap button accessories highlight the styAug 27, 2019 Plastic snap button to take the space to cool dowAug 27, 2019

Plastic snap button to take the space to cool dowAug 27, 2019 Fuming automatic buckle machine adapts to the timAug 27, 2019

Fuming automatic buckle machine adapts to the timAug 27, 2019 Fuming Button: A Brief Talk on the Development ofAug 27, 2019

Fuming Button: A Brief Talk on the Development ofAug 27, 2019